An RFID reader allows retailers to monitor customer selections and merchandising decisions, increasing engagement while yielding valuable insights.

Fixed readers create an interrogation zone and are mounted to carts or vehicles, featuring external antenna ports that can accommodate an additional antenna.

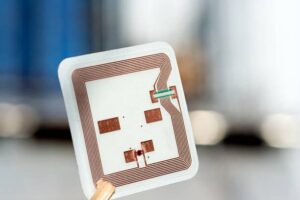

Antenna

An https://ramprfid.com RFID readers antenna emits radio waves that radiate a signal, making it critical to its success as it determines how far tags can be read and what data is recorded. An antenna may be external or integrated within an RFID reader itself, and its size and gain are also crucial determinants in its performance: higher gain antennas have stronger signals that allow them to reach farther. In contrast, low-gain ones have weaker ones with shorter reach capabilities.

An https://ramprfid.com RFID readers antenna emits radio waves that radiate a signal, making it critical to its success as it determines how far tags can be read and what data is recorded. An antenna may be external or integrated within an RFID reader itself, and its size and gain are also crucial determinants in its performance: higher gain antennas have stronger signals that allow them to reach farther. In contrast, low-gain ones have weaker ones with shorter reach capabilities.

RFID signals can be susceptible to interference from many sources, with multipath being the main culprit; when radio waves bounce off obstacles, they cause large-ranging errors, and interference is likely. Other sources include power lines, WiFi networks, motors and engines, which negatively affect system performance.

To reduce interference, an RFID reader should utilise a frequency-hopping technique. This technique allows them to avoid co-channel interference and frequency selective fading while at the same time selecting optimal frequencies for reading environments. Furthermore, an effective channel selection algorithm must also exist to determine optimal frequencies based on reading environments.

RFID readers are used in various industries to track inventory, improve workflows, and increase customer satisfaction. For example, an apparel retailer uses RFID readers in its fitting rooms to track inventory and customer behaviour – this allows the store to identify styles customers weren’t trying on and thus provides data that will enable it to sell more of these styles without needing assistance from sales associates.

An RFID reader consists of several parts, such as an antenna and transceiver. The antenna transmits a signal from https://ramprfid.com RFID readers to activate and power tags; this process takes only milliseconds. Meanwhile, transceivers convert antenna signals to usable power for transponders – UHF RFID readers even provide additional tracking information as part of this signal transmission.

Transceiver

Transceivers are integral components in communicating with RFID tags. The device transmits and receives radio frequency (RF) signals before translating them to data that can be transferred to a host computer or database for storage and analysis. Devices used for reading barcodes may be either handheld readers or fixed readers installed in warehouses, with handheld readers operating similarly to barcode scanners when operated with battery power. System users can immediately update RFID tag information with a keyboard and wirelessly connect it to database software. Fixed readers may be integrated into conveyor systems so pallets of inventory are automatically scanned as they pass. Vehicle-mounted readers are used for forklifts and other freight handling equipment to read cargo locations as it moves between storage locations or is reloaded or transferred.

As soon as an RFID reader approaches an item tagged with RFID technology, the radio-frequency (RF) signal emitted by its tag is backscattered off of its antenna on the reader. Once the reader detects this RF signal, and sends it directly to its data processing module, it is demodulated and translated into digital data before being retransmitted back into range to maintain communication links between the tag and reader.

RFID tags do not rely on line-of-sight communication like barcodes, enabling them to be used even in locations where people or objects might interfere with signals transmitted from readers. This opens up many opportunities in retail, logistics and other industries where there are multiple points of interaction with products or customers. For example, https://ramprfid.com RFID readers can be used to identify items as well as record activity, such as when customers select certain products or how often customers try on clothing items in a fitting room; one pilot project saw RFID readers installed in fitting rooms at a high-end fashion retailer where data gathered helped the company refine merchandise display and increase sales by monitoring clothing use across fitting rooms – data that helped improve merchandise display while growing sales through data collected during monitoring of clothing use across each room which enabled company management to improve merchandise display as well as sales results.

Though there may be safety concerns related to RFID technology in medical devices, physicians must stay aware of them and any possible risks that might apply to their patients. They should also ask their patients whether any exposure-related symptoms might have developed due to RFID readers and encourage them to report adverse events through MedWatch – the FDA’s voluntary reporting system for adverse events.

Chip

An RFID reader’s chip serves as the heart of its operation, detecting when an RFID tag comes within range of its antenna and transmitting a wireless signal that awakens it – with information about clock, data, energy usage and energy costs on board – awakening it and transmitting an energy charge back out to it via radio waves. When receiving this signal from its host antennae, an RFID tag receives it and returns a return message encoded with information such as its protocol version, managing organisation name and asset description, which are often stored as 96-bit strings of data called Electronic Product Code or EPC).

Once an https://ramprfid.com RFID readers tag receives a return signal from its reader, it modulates incoming radio waves to reflect them towards it – this process is known as backscatter. As soon as this occurs, signals reflect off it and are collected by an antenna within the RFID reader. They are later demodulated and relayed back out through various systems such as user servers or databases.

RFID tags enable businesses to track inventory, equipment, assets and people. Furthermore, their information allows companies to increase efficiency by decreasing labour costs and inventory carrying costs while improving accuracy. Hence, employees spend less time correcting errors and more time getting work done.

There are various RFID readers, each providing different forms of information. For example, some readers feature screens that automatically record when coming within range of a tag while others feature keyboards for immediate data input. They can be handheld or mounted, connected directly to PCs or mobile devices to send and receive data seamlessly.

RFID systems can track and manage various tools, machinery, and waste containers. For example, an RFID reader installed on garbage and recycling carts allows customers to bill for service verification easily; in addition, it monitors waste collection vehicles to ensure each is delivering equal waste loads; it even eliminates human error when measuring trash for accurate measurements, increasing productivity and accuracy – an invaluable asset in waste management companies’ toolbox.

Control Unit

An RFID reader uses radio waves to activate tags, read their information, and translate this back into a usable format for humans to access. This process usually takes less than a millisecond. Furthermore, an RFID reader may detect whether a tag signal has been transmitted multiple times – this phenomenon is known as probabilistic detection – indicating any illegal acts with it.

https://ramprfid.com RFID readers relay tag identification data back to a host system, which then records it into an electronic inventory database or storage repository for easy user access locally and remotely. With this information, retailers can track product movements within their supply chains while assuring customers receive precisely the required product. RFID technology is increasingly popular today, with leading manufacturers using it and COTS (commercial-off-the-shelf) RFID readers working with various kinds of cards from multiple manufacturers.

Readers come in various forms, from handheld devices for use by employees to fixed readers installed in secure areas. The type of reader used depends on its application; lower frequency readers are better suited for harsh environments as they’re less susceptible to interference from liquids and metal surfaces; however, higher frequency readers offer faster data reading rates but are more vulnerable to interference due to faster data reading rates but may become problematic during interference situations.

A reader can communicate with an RFID tag through an RF link or wired connection, with the former usually preferred due to its higher operating frequency allowing labels to be read from some distance away and can even be used to connect other systems.

Readers can range from handheld devices used by employees in warehouses and distribution centres to vehicle-mounted readers mounted on forklifts that offer hands-free scanning without leaving the truck. Fixed RFID readers placed within cabinets, doorways, or secure locations provide longer battery life and greater range than handheld readers